• Case Provider: Dr. Recep Uzgur

• Solution Used: Eighteeth Helios 500 Intraoral scanner and EXOCAD

• The workflow initiated with scanning using the Helios 500 and file importation into Exocad for further design andplanning for the screw-retained crown designing to be supported by the implant.

• About the Dentist

Dr. Recep Uzgur was born in Turkey in 1984. After graduating, he completed his PhD in Prosthodontics at Ankara University in 2014. Dr. Recep Uzgur is a key opinion leader for many companies such as Eighteeth, ltero, Dentsply Sirona. Asiga. 0sstem Implant, and Bredent lmplant, He is the fellow of the European Prosthodontic Association. He is also a member of various associations, including the Turkish Dental Association, the Turkish Prosthodontics and lmplantology Association, and the European Prosthodontic Association. Dr. Recep Uzgur's special interests are in esthetic dentistry, digital dentistry, and implantology.

• Case

A 38-year-old patient had the lower right first molar (tooth number 46) extracted three years ago.

The patient desires a permanent fixed replacement for the missing molar.

The patient was in good general health, and the medical history was not contributory at the time of treatment.

• Initial Situation and Treatment Planning

After thorough clinical and radiographic assessment, it was determined that a dental implant was the most suitable fixed solution for the missing tooth.

A 4 mm by 11.5 mm implant was selected for optimal fit and function.

The implant was successfully placed in the jaw three months ago following a two-stage surgical approach.

The first stage involved the placement of the implant into the jawbone, followed by a period of healing.

In the second stage, 12 weeks after the initial surgery, a healing cap was placed to promote proper gum tissue healing.

• Current Status and Treatment Process

At the time of the final impression, the implant had fully integrated with the bone and The soft tissue around the healing cap had also healed completely ready for impression step.

After confirming complete healing, the healing cap was carefully removed.

Following the removal, a compatible implant-level scan body was attached to the implant as per the manufacturer's instructions.

This scan body is used to accurately capture the implant's position and orientation, which is essential for designing the final prosthesis.

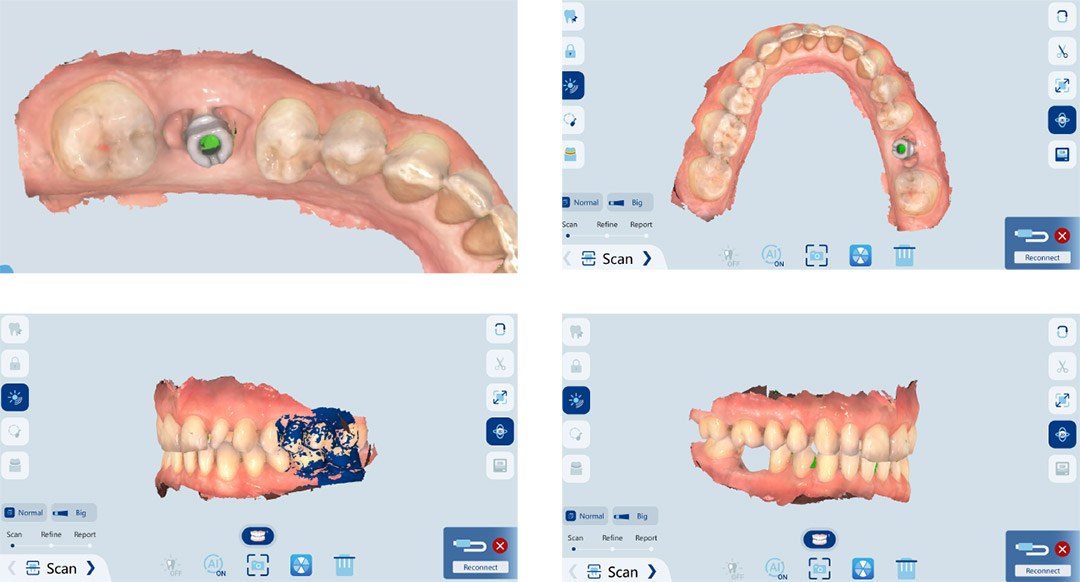

• lntraoral Scanning Protocol

An intraoral digital scan was carried out using the Helios 500 intraoral scanner, which captures precise 3D images of the teeth and gums of upper and lower jaws.

The procedure began with a comprehensive scan of the entire lower jaw, paying particular attention to the soft tissue where the tooth was missing.

Next, the opposing jaw which is upper was scanned.

The patient was instructed to bite down in maximum intercuspation, allowing for a buccal scan which captures the way the teeth fit together from the buccal side.

Following the Helios software's protocol, a specific circular section of the target scan area was cut and isolated for detailed imaging.

Subsequently, only this defined area was re-scanned with the scan body in place.

The software swiftly merged and aligned both scans, combining the detailed section with the overall oral structure within seconds.

• Design and Milling

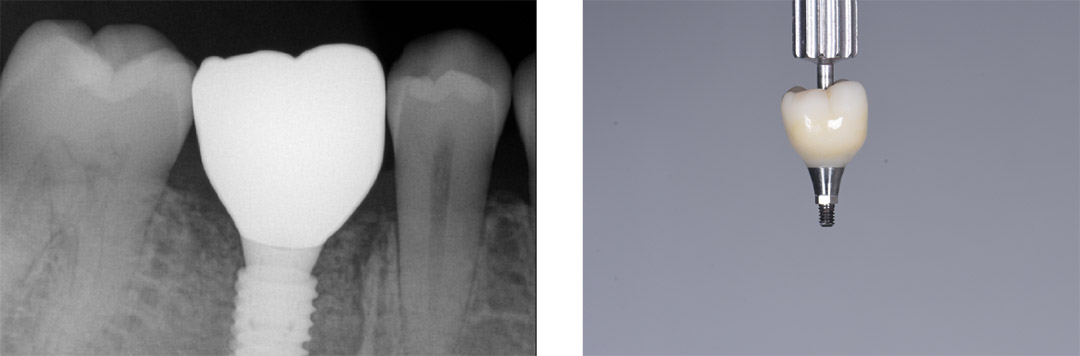

After the digital impressions were taken of the upper and lower jaws and bite, the STL files were sent to our in-house exocad software for design.

A screw-retained crown was designed to be supported by the implant. This crown was then precisely milled using the Redon GTR unit.

After an overnight sintering process of 6 hours for durability, the crown was stained and glazed to match the natural teeth, completing the restoration.

Following the design and creation process, the crown was then adhesively cemented to its titanium base abutment, making it ready for placement in the patient's mouth.

• Placement of the Crown in the Mouth

After preparing the crown for intraoral placement, it was positioned at its designated site.

Subseauently, the occlusion and contact with neighboring teeth were meticulously checked to ensure proper alignment and function.

Verification of the implant and crown alignment was confirmed with a periapical X-ray. Once everything was confirmed to be correct, the screw hole was sealed with Teflon and a flowable composite to finalize the placement.

• Verification with Periapical X-Ray

• Comment of Dentist

In this case, the Helios 500 intraoral scanner was utilized, facilitating a fully digital workflow.

The capture process for each jaw took less than one minute.

After production, it was contirmed that the crown was perfectly seated in its place, with accurate contacts and occlusion.

consequently, the case was successfully completed within 24 hours.