• Case Provider: Dr. Recep Uzgur

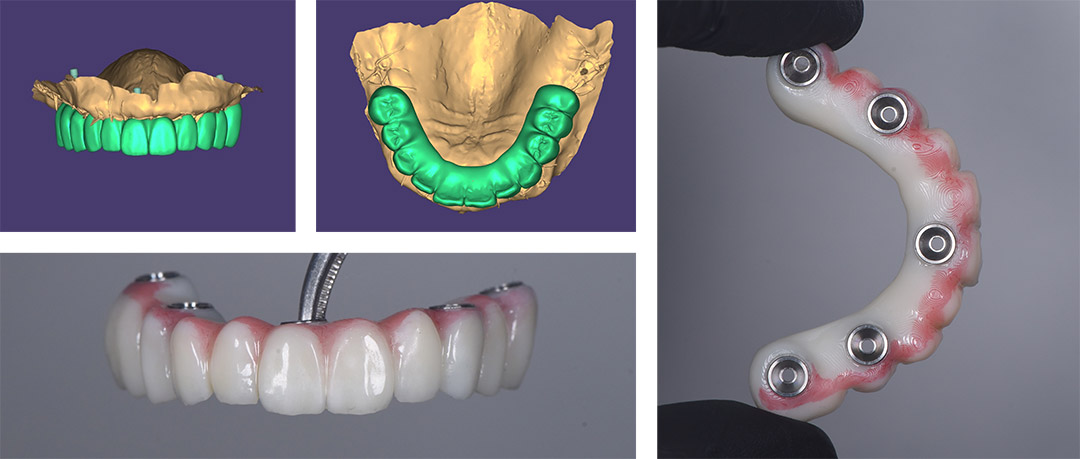

• Solution Used: Eighteeth Helios 500 Intraoral scanner and EXOCAD

• The workflow initiated with scanning using the Helios 500 and file importation into Exocad for further design.

• About the Dentist

Dr. Recep Uzgur was born in Turkey in 1984. After graduating, he completed his PhD in Prosthodontics at Ankara University in 2014. Dr. Recep Uzgur is a key opinion leader for many companies such as Eighteeth, ltero, Dentsply Sirona, Asiga, Osstem Implant, and Bredent lmplant. He is the fellow of the European Prosthodontic Association. He is also a member ofvarious associations, including the Turkish Dental Association, the Turkish Prosthodontics and lmplantology Association, and the European Prosthodontic Association, Dr., Recep Uzgur's special interests are in esthetic dentistry, digital dentistry, and implantology.

• Case

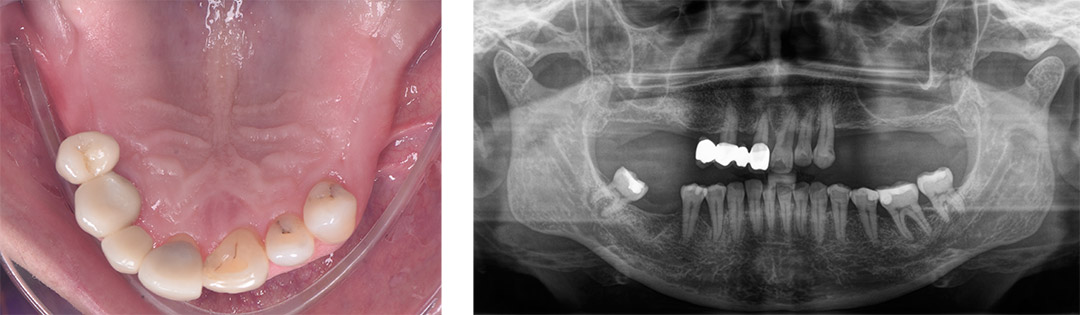

A 46-year-old female patient presented to our clinic with severely compromised teeth.

Despite being a long-term periodontal patient under regular follow-up and treatment, she had lost most of her teeth and retained only six, all of which were periodontally compromised. She sought a fixed dental rehabilitation solution.

• Treatment Planning

During the clinical examination and radiological assessment, it was noted that the remaining teeth exhibited grade 2 mobility. Hence, the decision was made to extract all remaining teeth and place five implants, followed by immediate prosthesis placement if the specified torque ratings were achieved.

• Treatment Process

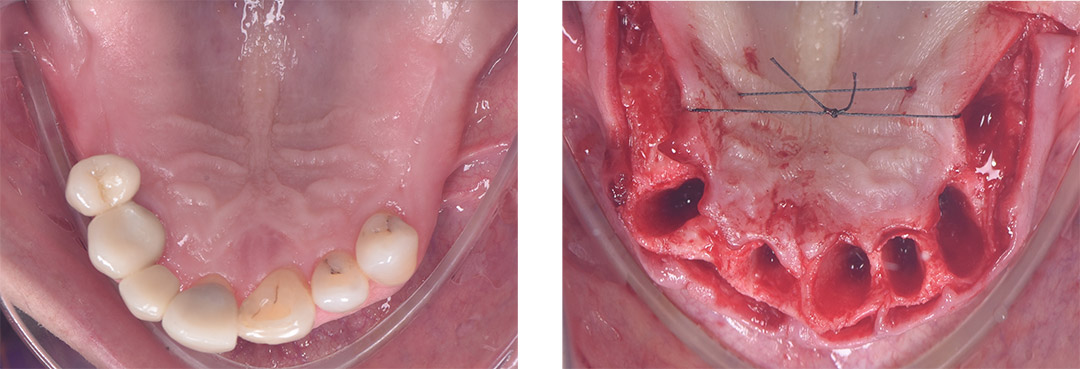

After adequate local anesthesia was administered to the upper jaw, all remaining teeth were extracted. The granulation tissue was thoroughly curetted, and the apex and walls of the extraction sockets were meticulously cleaned.

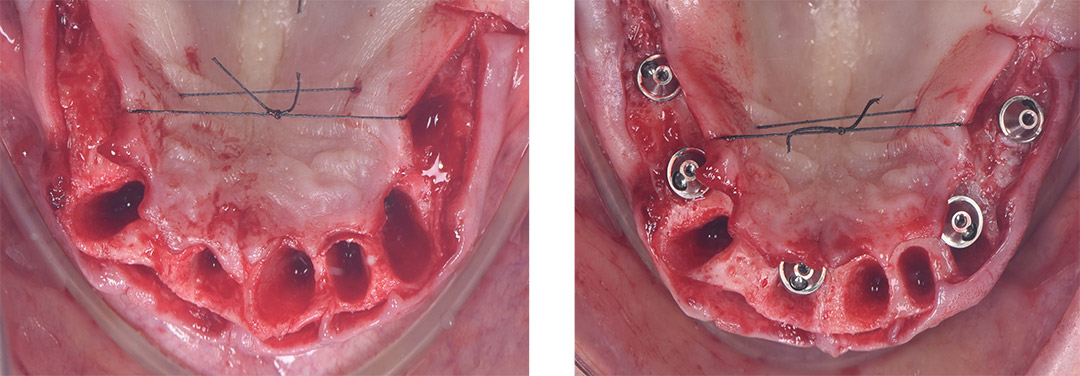

Following the extractions, a full-thickness flap was raised and tied palatally to enhance visibility of the bone. Five implants were placed according to the clinical and radiological plan. Multi-unit abutments were attached prior to suturing. As a temporary prosthesis was to be fabricated using a digital workflow, scan bodies were screwed onto the multi-unit abutments.

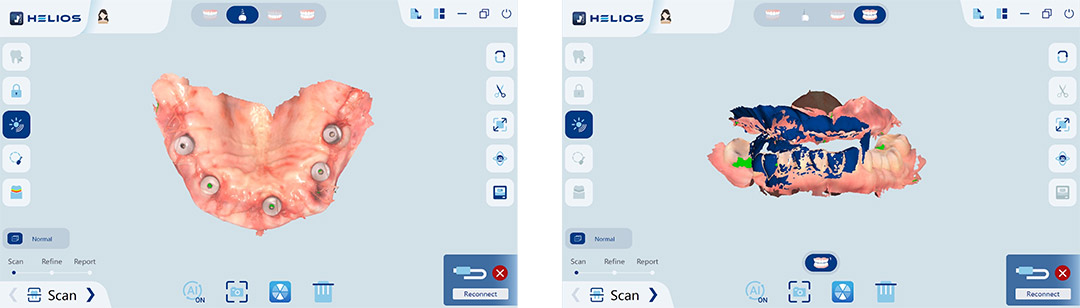

• Intraoral Scanning Protocol

A precise digital scanning protocol was followed. First, the upper arch was scanned, followed by the lower arch. Buccal scans were performed bilaterally to improve the accuracy of the impression. The upper arch was scanned both with scan bodies and without, capturing only the soft tissue. The advanced Al of the Helios 500 scanner optimized the buccal scanning stage, correcting any potential errors due to operator or patient movement.

• Design and 3D Printing

The design of the temporary prosthesis was completed using exocad. To minimize lateral forces, no cantilever was included in the temporary design. The temporary prosthesis was then fabricated using a 3D printer.

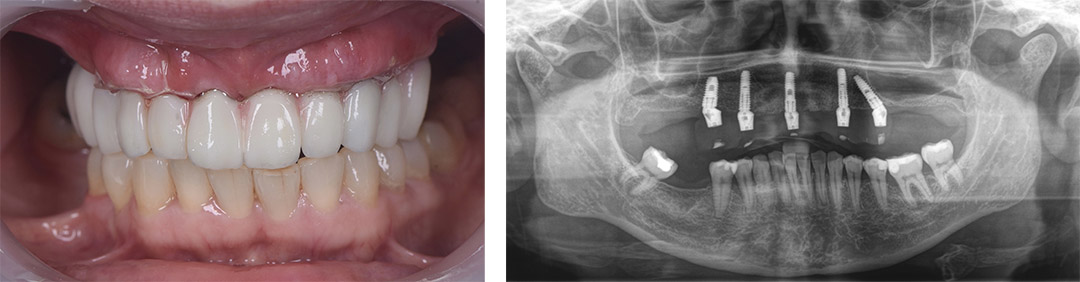

• Plecement of Temporary

Post 3D printing, multi-tibases were adhesively bonded to the temporary prosthesis, making it ready for placement. The temporary prosthesis was positioned in the mouth, and the screw access holes were sealed with Teflon tape and flowable composite.

• Verification with Periapical X-Ray

• Comment of Dentist

For this particular treatment, the Helios 500 intraoral scanner was employed, ensuring a streamlined and entirely digital workflow.

A digital workflow was utilized for this treatment. Despite the operation on the upper jaw, including sutures and minor bleeding, the Helios 500 successfully performed soft tissue and scan body scanning.

The impression was completed in less than 7 minutes. The design process took approximately 60 minutes, and the 3D printing process also took around 60 minutes.

For this type of case, the time between digital impression and the placement of the temporary prosthesis was approximately 3 hours.