• Case Provider: Dr. Recep Uzgur

• Solution Used: Eighteeth Helios 500 Intraoral scanner and EXOCAD

• The workflow initiated with scanning using the Helios 500 and file importation into Exocad for further design.

• About the Dentist

Dr. Recep Uzgur was born in Turkey in 1984. After graduating, he completed his PhD in Prosthodontics at Ankara University in 2014. Dr. Recep Uzgur is a key opinion leader for many companies such as Eighteeth, ltero, Dentsply Sirona, Asiga, Osstem Implant, and Bredent mplant. He is the fellow of the European Prosthodontic Association. He is also a member of various associations, including the Turkish DentalAssociation, the Turkish Prosthodontics and lmplantoloey Association, and the European Prosthodontic Association. Dr. Recep Uzgur's special interests are in esthetic dentistry, digital dentistry, and implantology.

• Case

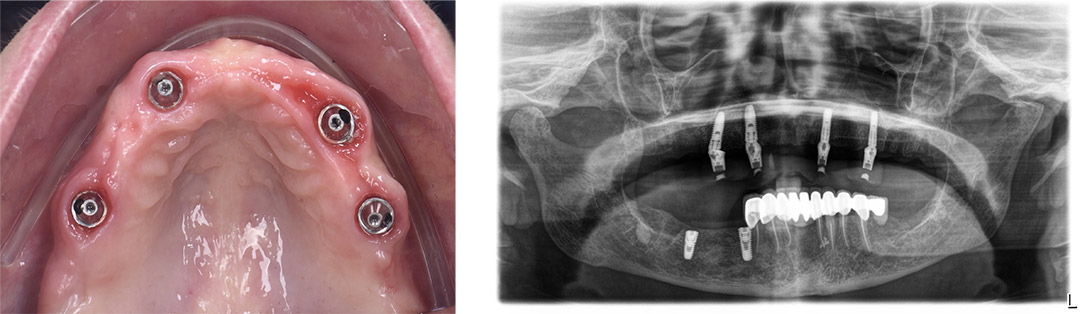

A 66-year-old female patient with a pre-established treatment plan and osseointegrated implants presented to our clinic for her final prosthesis. Patient have had four (4) implant with good AP distribution.

• Treatment Planning

The patient previously had her teeth extracted and four implants placed. To achieve the best aesthetic outcome, zirconia was chosen as the restorative material. Given the inter-implant distances and the likelihood of two or more pontics, it was decided to support the zirconia material with a titanium bar. This plan was devised to avoid fractures in long-term treatments.

• Treatment Process

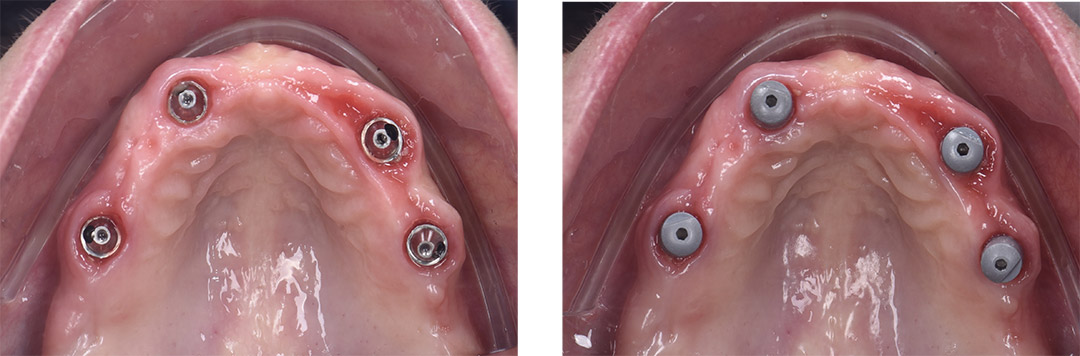

The patient' s immediately loaded temporary prostheses were removed, and after rechecking the torque of the multi-units, multi-unit scan bodies were placed. An intraoral scan was then performed for full-arch rehabilitation.

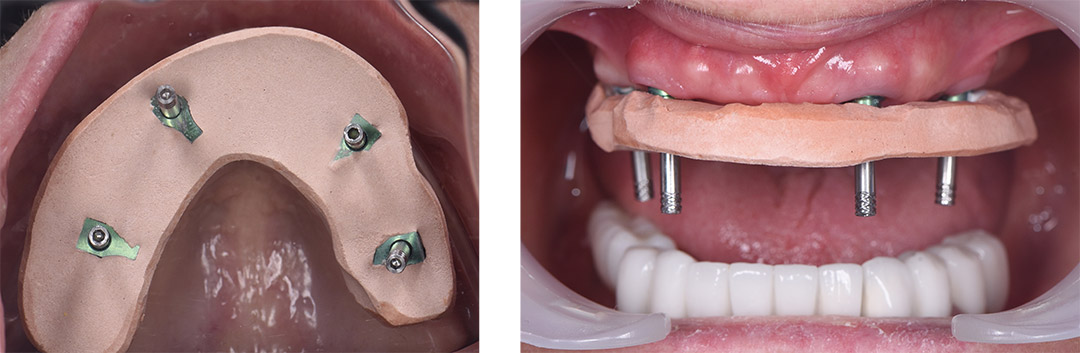

To verify the digital impressions, a model was prepared using a 3D printer. On this model, a verification jig made of plaster, known as the best method for accurate control, was created. The impression was then confirmed using this jig.

• Intraoral Scanning Protocol

For this procedure, the Helios 500 intraoral scanner was used. The scanning process involved scanning the upper arch first, followed by the lower arch, and then the buccal scan. in the upper arch scan, the soft tissues were scanned first, followed by the scan bodies. The lower arch scan was then completed, For the occlusal scan, the patient's previously immediately loaded temporary prosthesis, which had been used for approximately three months, was placed in the mouth to complete the buccal scan.

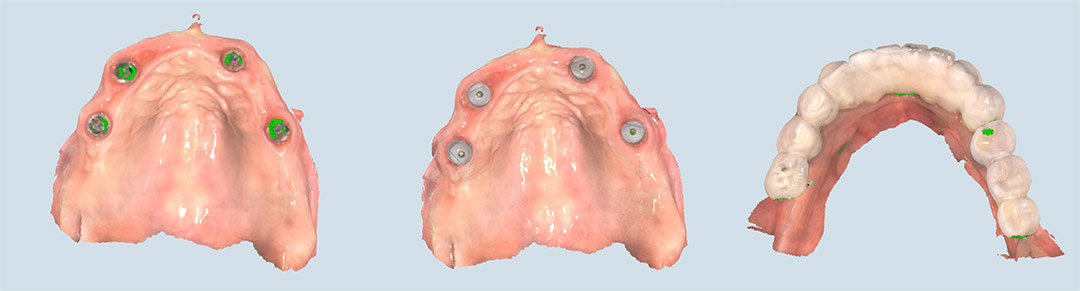

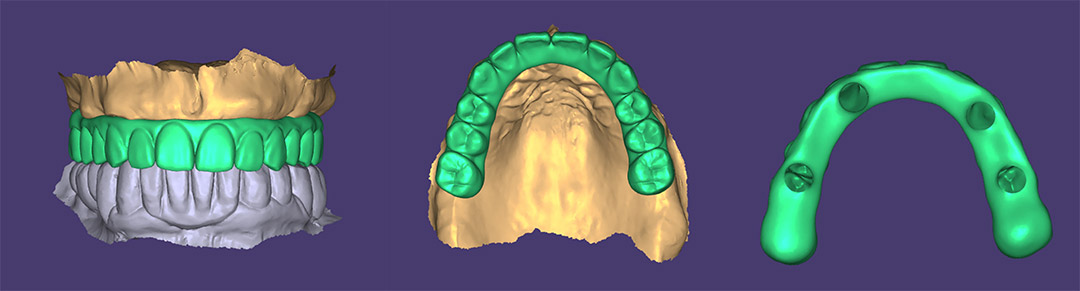

• Design and 3D Printing

The digital impressions were transferred to Exocad, where the desired design was completed. Before proceeding with the final prosthesis fabrication, the design was 3D printed to create a trial fixed prosthesis. This trial prosthesis was then placed in the patient's mouth by screwing it in, allowing for the verification of aesthetic and functional elements such as the midline, smile line, tooth axes, and vertical dimension in a full-arch restoration. The patient was also able to see and approve the trial.

• Final Milling

Following this trial, and upon approval by both the dentist and the patient, the design was exported from Exocad and imported into Blender software. The design was then separated into two parts: the titanium bar and the zirconia upper structure. Orders for the production of these components were placed, and the fabrications were completed shortly thereafter.

• Try In and Adhesive Cementation

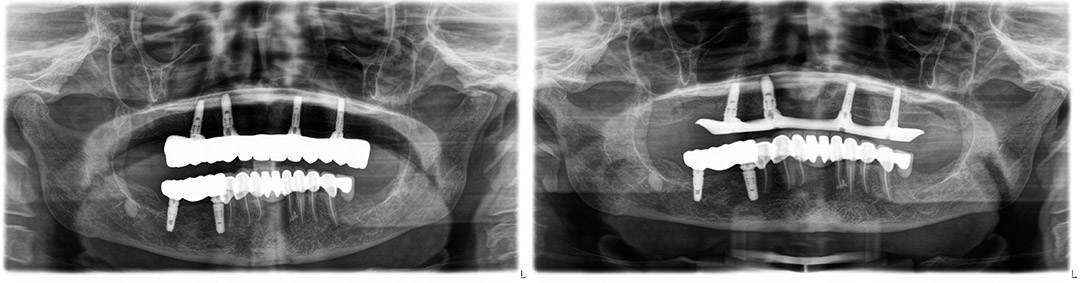

After the production of the titanium bar and the zirconia superstructure, the titanium bar was trial-fitted in the patient's mouth to ensure everything was functioning correctly, Following the confirmation of a passive fit, the final zirconia superstructure was adhesively bonded to the titanium bar on the model.

• Final Prosthesis

After completing the adhesive bonding of the final prosthesis, it was screwed into place in the patient's mouth, and the occlusion was checked, Once evervthing was confirmed to be perfect, the screw access holes were sealed with teflon and flowable composite.

• Verification of Ti-Bar and Final Prosthesis with Panoramic X-Ray

• Comment of Dentist

The error-free acquisition of digital impressions for full-arch restorations using intraoral scanners has not yet been definitively established in the literature.

Therefore, it is important to verify full-arch restoration impressions taken with intraoral scanners using an analog method.

The accuracy of full-arch implant impressions can be affected by several factors, including the distance between implants, the number of implants, their angulation, and the shape of the arch.

In this and many other cases, the author has verified the impressions taken with the Helios 500 using a plaster model, often resulting in passive and successful fits.

This type of challenging case was successfully completed using the Helios 500 scanner.